Hyundai ayuda a los famosos arqueros de Corea del Sur a dar en el blanco con el Artec Spider II

Desafío: empuñaduras a la medida para arqueros surcoreanos respaldados por Hyundai, para que sus arcos brinden la estabilidad increíblemente alta necesaria para competir al más alto nivel del deporte.

Solución: Artec Spider II, Artec Studio, Geomagic Design X.

Resultado: puños con mayor durabilidad, adaptados a las necesidades de los atletas individuales. Fabricados con impresión 3D, estos dispositivos se pueden personalizar al vuelo con menos ensayo y error. Los arqueros coreanos ahora pueden disparar flechas con mayor estabilidad, manteniendo su puntería para mejorar la precisión del disparo.

¿Por qué Artec 3D?: Capaz de capturar con una precisión y resolución de hasta 0,05 mm, el Artec Spider II es perfecto para digitalizar geometrías complejas de arcos con gran detalle. La computadora portátil también recoge superficies oscuras y brillantes sin rociar, a diferencia de muchas alternativas en el mercado.

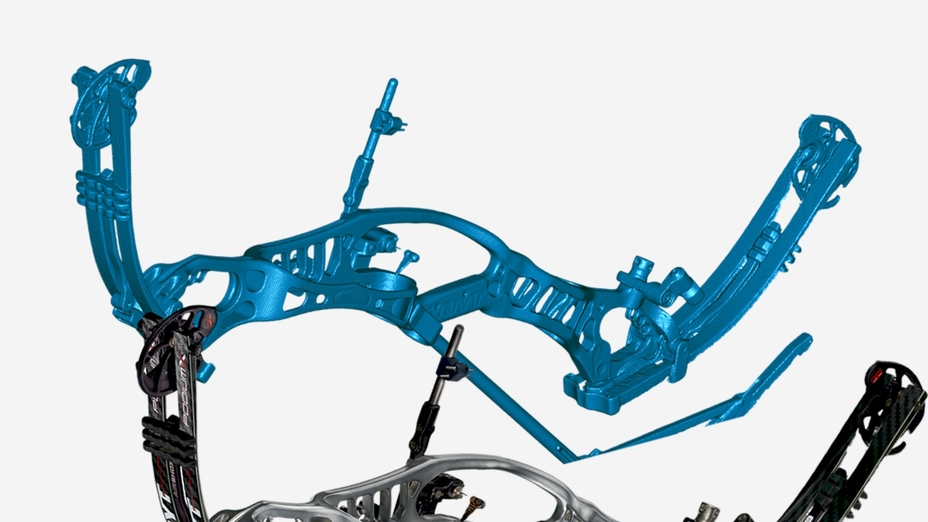

El Gerente de Ventas y Marketing de Inozard, Danny Ahn, escaneó en 3D el arco con un Spider II. Imagen cortesía de Inozard.

En el mundo moderno, Corea del Sur es quizás mejor conocida por sus ciudades de alta tecnología, su floreciente escena pop y sus icónicos programas de televisión y películas, que están capturando cada vez más a una audiencia internacional. Pero el país también tiene un pasado fascinante arraigado en tradiciones centenarias, muchas de las cuales continúan observándose, y los deportes tradicionales como el tiro con arco siguen siendo muy populares.

El tiro con arco está profundamente arraigado en la cultura coreana. Conocida como gungdo (궁도) o gungsul (궁술), la disciplina fue fundamental para la cultura detrás de los aún idealizados Hwarang (화랑), o «los Caballeros de las Flores» del siglo VII. Desde que el deporte se reintrodujo en Corea en 1959, ha recuperado la imaginación del público y su escena de tiro con arco, ferozmente competitiva, continúa floreciendo.

Cuando consideras que los arqueros tienen que golpear un objetivo del tamaño de la palma de la mano desde un rango de 70 metros, está claro por qué el deporte es tan respetado allí. La concentración y la disciplina son clave. Los competidores también dependen en gran medida de su equipo, en particular de los agarres de tiro con arco. Estos dispositivos (a menudo temporales) ayudan a los arqueros a colocar sus manos de manera cómoda, consistente y con un alto grado de control.

Sin embargo, en un deporte de márgenes finos, la desviación y falta de durabilidad agregan un factor desconocido al conjunto de variables, con el potencial de desestabilizar a los arqueros de tiro caliente. Es por eso que Hyundai, un patrocinador desde hace mucho tiempo del tiro con arco coreano, se acercó al distribuidor de confianza de Artec 3D Inozard. Juntos, ahora crean agarres personalizados para los mejores arqueros del país, con la ayuda del escaneo 3D del Artec Spider II.

Digitalizar lazos para un ajuste perfecto

Hyundai es conocida por su experiencia en automoción, pero la empresa opera en muchas otras áreas, como la industria pesada y el sector marítimo. Aquí es donde Inozard comenzó a trabajar con la empresa en el desarrollo de piezas para barcos. Una vez que Hyundai vio al equipo en acción, también les pidió que echaran un vistazo a los agarres que usaban sus arqueros en la competencia.

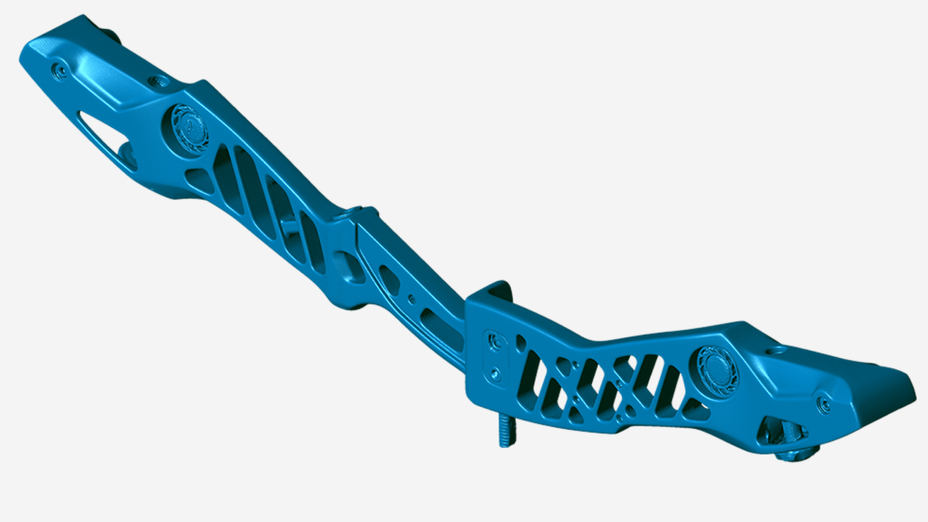

Malla 3D del arco digitalizado dentro de Artec Studio. Imagen cortesía de Inozard.

Muchos atletas dependían de una cinta rudimentaria, lo que conducía a niveles inconsistentes de agarre. La cinta también se desgasta rápidamente, requiere reemplazo y no permite mucha personalización.

Para ayudar a estos arqueros a maximizar su rendimiento, Inozard comenzó a trabajar en una alternativa hecha a la medida, que se construiría alrededor de gemelos digitales de sus arcos individuales. Según Danny Ahn, Gerente de Ventas y Marketing de Inozard, el Artec Leo inalámbrico impulsado por IA habría hecho el trabajo, pero en su lugar usaron el nuevo Spider II para capturar con la máxima precisión y resolución.

Naturalmente, los arcos presentan geometrías estrechas y superficies oscuras y ligeramente brillantes. Normalmente, esto requeriría el uso de aerosol de escaneo, pero no con el Spider II. El dispositivo alimentado por luz azul permitió la captura rápida y sin problemas incluso de los detalles más finos, proporcionando a Inozard los datos de superficie 3D necesarios para construir y crear equipos de tiro con arco altamente personalizados.

«Una vez creí que los escáneres de luz estructurada montados en trípode eran los mejores del mundo. Pero ahora he cambiado de opinión», explicó Ahn. «El Spider II es fácil de usar, portátil, de mano, y el seguimiento es mucho mejor que el Space Spider original. ¿Qué puedo decir? Es tan fluido, escanea perfectamente y la precisión es simplemente excelente».

Diseño e impresión 3D de empuñaduras personalizadas

El flujo de trabajo de Inozard comenzó con el desenroscado de los agarres regulares de los atletas. Estos dispositivos fueron escaneados en 3D junto con los arcos y sometidos a ingeniería inversa. En la práctica, esto significaba procesar los datos capturados dentro de Artec Studio, un software repleto de todos los elementos esenciales para la alineación, fusión, eliminación de valores atípicos; y también el diezmado, con el fin de reducir el tamaño del archivo.

Una versión completamente texturizada del arco, capturada con el escáner 3D Spider II. Imagen cortesía de Inozard.

La perfecta integración con Geomagic Design X facilitó la importación de modelos y su uso como base para diseñar empuñaduras que encajaran perfectamente en los arcos de los atletas. Garantizar un ajuste perfecto significaba crear prototipos de los dispositivos. Para acelerar este proceso, Inozard optó por iterar en cada diseño utilizando la impresión 3D SLS, una tecnología conocida por ofrecer piezas de alta durabilidad.

En general, este enfoque permitió a su equipo capturar y procesar datos en sólo una o dos horas, y los diseños finales de agarre estuvieron listos para la impresión 3D después de un par de días. Con estos dispositivos, que se personalizan para satisfacer las necesidades específicas de los arqueros, los atletas de Hyundai ahora pueden competir con una ergonomía mejorada y cambiar las cosas como mejor les parezca para obtener mejores resultados.

«Hay muchas opciones de personalización: realizamos ingeniería inversa basada en la superficie de la cinta, modificamos el agarre a los contornos individuales de los atletas y luego probamos la impresión», agregó Ahn. «Podemos personalizarlo una y otra vez: como somos una empresa de impresión 3D, podemos hacer muchos de ellos a la vez. En realidad, cada atleta tiene de 6 a 10 agarres. Son duraderos, pero aun así, a medida que pasa el tiempo, puede comenzar a sentirse diferente. Ahora, pueden cambiarlo rápidamente por uno nuevo».

Expandirse a nuevas disciplinas

Ahora utilizados en competiciones internacionales de tiro con arco en todo el mundo, se espera que estos agarres personalizados sean los primeros de muchos. Inozard expuso recientemente en una exhibición de tiro con arco, donde muchos otros atletas y estudiantes universitarios mostraron interés en su tecnología.

Ya sea en tenis, bádminton o cualquier otro deporte cuyos agarres dependan de robustez, Inozard ve un potencial significativo para futuras aplicaciones, especialmente dados sus beneficios comprobados de costo y tiempo de entrega.

Inozard también capturó un modelo menos detallado del arco usando un Artec Leo para mostrar la versatilidad del escáner 3D inalámbrico. Imagen cortesía de Inozard.

«El precio no es muy alto: después de escanear una vez, puede usar el modelo todo el tiempo para crear muchos agarres u otras partes», concluyó Ahn. «En general, creo que el precio será competitivo en este mercado. También creo que es posible establecer un servicio de escaneo o procesamiento 3D para esta aplicación en el futuro. Estamos viendo una gran demanda de este tipo de atletas».

Hasta el día de hoy, los arqueros coreanos continúan compitiendo por los máximos honores tanto en las disciplinas masculinas como femeninas. El equipo de Inozard está muy orgulloso de haber ayudado al país a mantener viva su tradición, y esperan que el proyecto sirva como prueba conceptual para futuras empresas deportivas.

Escáneres detrás de la historia

Prueba los escáneres 3D líderes en el mundo.